-

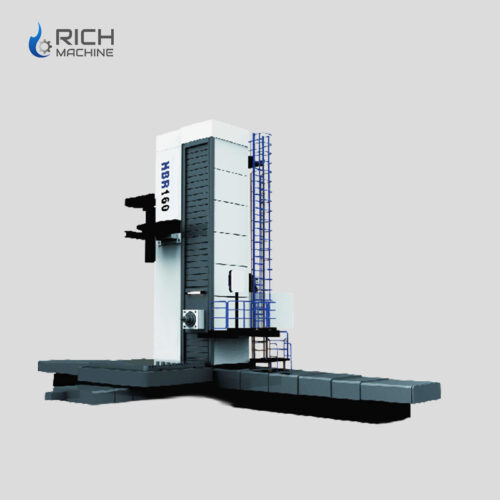

High-rigidity -The main shaft bearing is cooled by circulating oil, and the surrounding is equipped with tubing jacket cooling design to acoid thermal displacement. -The flange part of the main shaft is cooled by oil pipe sheath. -After special nitriding treatment, the main shaft can be used for a long time without wearing. -X/Y/Z shaft guide screw and motor adopt reducer direct-type transmission mechanism.

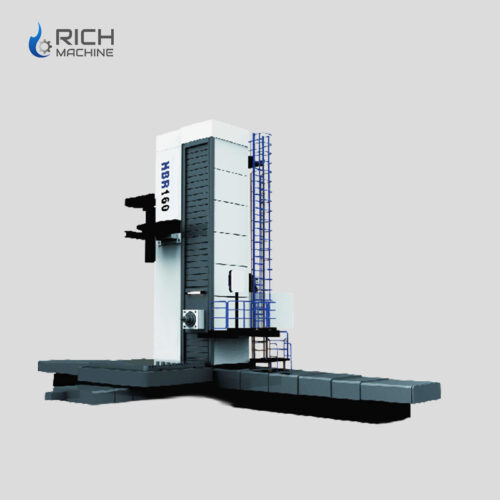

High-rigidity -The main shaft bearing is cooled by circulating oil, and the surrounding is equipped with tubing jacket cooling design to acoid thermal displacement. -The flange part of the main shaft is cooled by oil pipe sheath. -After special nitriding treatment, the main shaft can be used for a long time without wearing. -X/Y/Z shaft guide screw and motor adopt reducer direct-type transmission mechanism. -

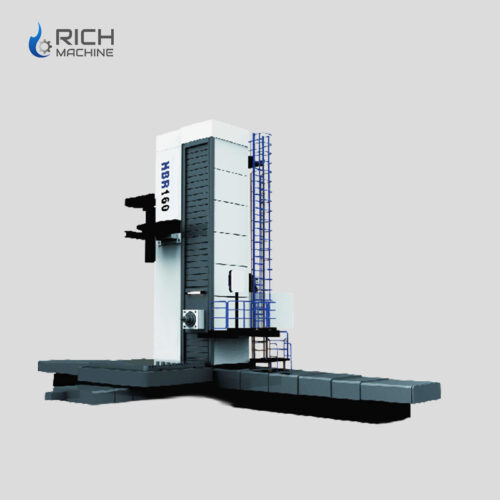

High-rigidity -The main shaft bearing is cooled by circulating oil, and the surrounding is equipped with tubing jacket cooling design to acoid thermal displacement. -The flange part of the main shaft is cooled by oil pipe sheath. -After special nitriding treatment, the main shaft can be used for a long time without wearing. -X/Y/Z shaft guide screw and motor adopt reducer direct-type transmission mechanism.

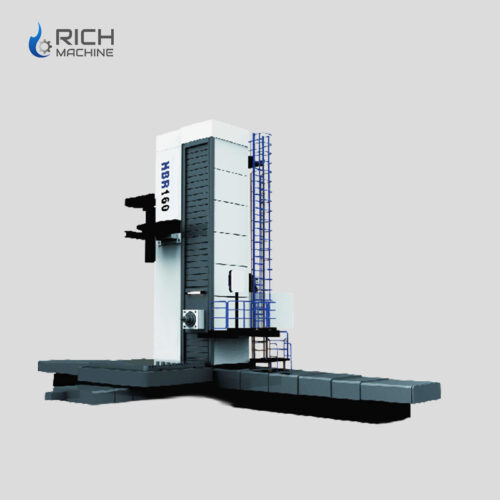

High-rigidity -The main shaft bearing is cooled by circulating oil, and the surrounding is equipped with tubing jacket cooling design to acoid thermal displacement. -The flange part of the main shaft is cooled by oil pipe sheath. -After special nitriding treatment, the main shaft can be used for a long time without wearing. -X/Y/Z shaft guide screw and motor adopt reducer direct-type transmission mechanism. -

High-rigidity -The main shaft bearing is cooled by circulating oil, and the surrounding is equipped with tubing jacket cooling design to acoid thermal displacement. -The flange part of the main shaft is cooled by oil pipe sheath. -After special nitriding treatment, the main shaft can be used for a long time without wearing. -X/Y/Z shaft guide screw and motor adopt reducer direct-type transmission mechanism.

High-rigidity -The main shaft bearing is cooled by circulating oil, and the surrounding is equipped with tubing jacket cooling design to acoid thermal displacement. -The flange part of the main shaft is cooled by oil pipe sheath. -After special nitriding treatment, the main shaft can be used for a long time without wearing. -X/Y/Z shaft guide screw and motor adopt reducer direct-type transmission mechanism. -

High-rigidity -The main shaft bearing is cooled by circulating oil, and the surrounding is equipped with tubing jacket cooling design to acoid thermal displacement. -The flange part of the main shaft is cooled by oil pipe sheath. -After special nitriding treatment, the main shaft can be used for a long time without wearing. -X/Y/Z shaft guide screw and motor adopt reducer direct-type transmission mechanism.

High-rigidity -The main shaft bearing is cooled by circulating oil, and the surrounding is equipped with tubing jacket cooling design to acoid thermal displacement. -The flange part of the main shaft is cooled by oil pipe sheath. -After special nitriding treatment, the main shaft can be used for a long time without wearing. -X/Y/Z shaft guide screw and motor adopt reducer direct-type transmission mechanism. -

High-rigidity -The main shaft bearing is cooled by circulating oil, and the surrounding is equipped with tubing jacket cooling design to acoid thermal displacement. -The flange part of the main shaft is cooled by oil pipe sheath. -After special nitriding treatment, the main shaft can be used for a long time without wearing. -X/Y/Z shaft guide screw and motor adopt reducer direct-type transmission mechanism.

High-rigidity -The main shaft bearing is cooled by circulating oil, and the surrounding is equipped with tubing jacket cooling design to acoid thermal displacement. -The flange part of the main shaft is cooled by oil pipe sheath. -After special nitriding treatment, the main shaft can be used for a long time without wearing. -X/Y/Z shaft guide screw and motor adopt reducer direct-type transmission mechanism. -

Product Feactures: -The basic parts of the machine tool (bed, column, spindle box, etc.) are all made of high-quality cast iron and resin sand, and are aged twice by electric fumace. The bed body of the machine toll is a closed box-type structure with reasonable arrangement of reinforcing ribs and multi-point support. -Machine tool has autoatic chip removal and tool external cooling device, and can provide automatic toll change device, spindle tool internal cooling function configuration options to meet the needs of users.

Product Feactures: -The basic parts of the machine tool (bed, column, spindle box, etc.) are all made of high-quality cast iron and resin sand, and are aged twice by electric fumace. The bed body of the machine toll is a closed box-type structure with reasonable arrangement of reinforcing ribs and multi-point support. -Machine tool has autoatic chip removal and tool external cooling device, and can provide automatic toll change device, spindle tool internal cooling function configuration options to meet the needs of users. -

Product Feactures: -The basic parts of the machine tool (bed, column, spindle box, etc.) are all made of high-quality cast iron and resin sand, and are aged twice by electric fumace. The bed body of the machine toll is a closed box-type structure with reasonable arrangement of reinforcing ribs and multi-point support. -Machine tool has autoatic chip removal and tool external cooling device, and can provide automatic toll change device, spindle tool internal cooling function configuration options to meet the needs of users.

Product Feactures: -The basic parts of the machine tool (bed, column, spindle box, etc.) are all made of high-quality cast iron and resin sand, and are aged twice by electric fumace. The bed body of the machine toll is a closed box-type structure with reasonable arrangement of reinforcing ribs and multi-point support. -Machine tool has autoatic chip removal and tool external cooling device, and can provide automatic toll change device, spindle tool internal cooling function configuration options to meet the needs of users. -

Product Feactures: -The basic parts of the machine tool (bed, column, spindle box, etc.) are all made of high-quality cast iron and resin sand, and are aged twice by electric fumace. The bed body of the machine toll is a closed box-type structure with reasonable arrangement of reinforcing ribs and multi-point support. -Machine tool has autoatic chip removal and tool external cooling device, and can provide automatic toll change device, spindle tool internal cooling function configuration options to meet the needs of users.

Product Feactures: -The basic parts of the machine tool (bed, column, spindle box, etc.) are all made of high-quality cast iron and resin sand, and are aged twice by electric fumace. The bed body of the machine toll is a closed box-type structure with reasonable arrangement of reinforcing ribs and multi-point support. -Machine tool has autoatic chip removal and tool external cooling device, and can provide automatic toll change device, spindle tool internal cooling function configuration options to meet the needs of users. -

Product Feactures: -The basic parts of the machine tool (bed, column, spindle box, etc.) are all made of high-quality cast iron and resin sand, and are aged twice by electric fumace. The bed body of the machine toll is a closed box-type structure with reasonable arrangement of reinforcing ribs and multi-point support. -Machine tool has autoatic chip removal and tool external cooling device, and can provide automatic toll change device, spindle tool internal cooling function configuration options to meet the needs of users.

Product Feactures: -The basic parts of the machine tool (bed, column, spindle box, etc.) are all made of high-quality cast iron and resin sand, and are aged twice by electric fumace. The bed body of the machine toll is a closed box-type structure with reasonable arrangement of reinforcing ribs and multi-point support. -Machine tool has autoatic chip removal and tool external cooling device, and can provide automatic toll change device, spindle tool internal cooling function configuration options to meet the needs of users.