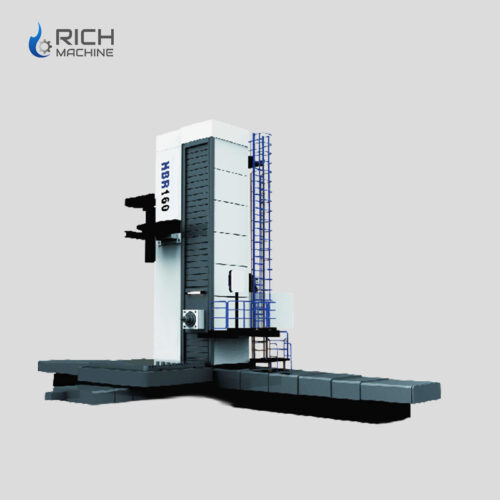

Description

Product Features:

High-torque

-The max torque output of the main shaft is 2838Nm, which is the largest of similar products.

-The nose type spindle head can approach the workpiece when machining and is suitable for heavy cutting.

-The rotaing workbench is equiped with a standard bearing capacity of 8000kg and an optonal bearing capacity of 1000-25000kg.

-The z-axis cam continously bear the axial load of 2000kg, ensuring high torque and high speed to provide extremely high cutting force.

High-rigidity

-The main shaft bearing is cooled by circulating oil, and the surrounding is equipped with tubing jacket cooling design to acoid thermal displacement.

-The flange part of the main shaft is cooled by oil pipe sheath.

-After special nitriding treatment, the main shaft can be used for a long time without wearing.

-X/Y/Z shaft guide screw and motor adopt reducer direct-type transmission mechanism.

High-precision

-The casting structure is composed of high-grade cast iron with good stability and strong seismic resistance and arch bridge type high rigid structure.

-The bending and torsional rigidity of the column is increased by 1.7 times, and the stable processing can be carried out on the top side of the Y-axis strike end.

-The combination of the spindle treated bu nitriding and untra deep cooling(-190℃)and the spindle bearing with high precision and rigidity can give full paly to the best performance of the product for a long time.

Reviews

There are no reviews yet.