-

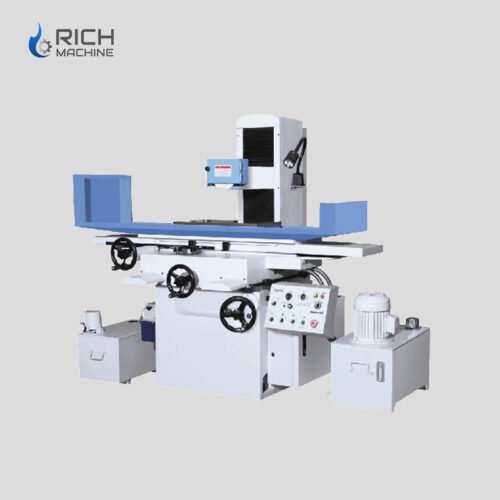

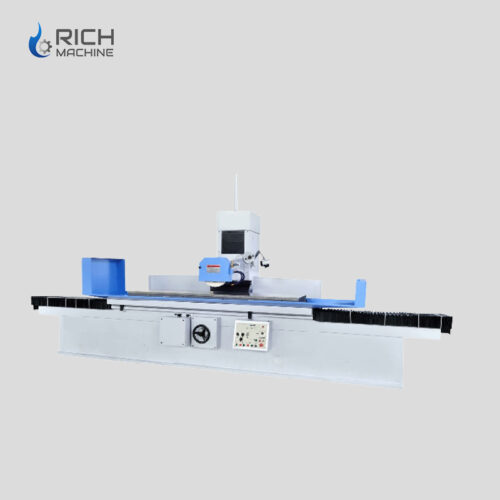

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration under high-speed rotation, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China, with low noise and low temperature rise.

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration under high-speed rotation, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China, with low noise and low temperature rise. -

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration under high-speed rotation, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China, with low noise and low temperature rise.

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration under high-speed rotation, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China, with low noise and low temperature rise. -

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration under high-speed rotation, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China, with low noise and low temperature rise.

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration under high-speed rotation, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China, with low noise and low temperature rise. -

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration under high-speed rotation, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China, with low noise and low temperature rise.

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration under high-speed rotation, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China, with low noise and low temperature rise. -

Main Features: ◆High rigidity structure The machine tool body is an integrated structural design. The main castings such as the base, saddle, worktable, frame, spindle head, etc. are all made of high-grade cast iron (FC30) and annealed to eliminate internal stress and ensure the stability of the machine. It also gives full play to the ability of high-precision heavy chip cutting, shortens the grinding time, and improves the working efficiency. ◆High precision The high-precision machine track adopts a double V-shaped track design to ensure the stability of the machine tool worktable. The track is precisely scraped manually to ensure long-lasting accuracy. The feed is smooth and not easy to wear. In addition, the worktable track lubrication is independent lubrication to avoid inaccurate accuracy caused by the heating of the track oil. ◆Precise and strong spindle The spindle adopts imported P4-level precision bearings, with low noise and good precision. The spindle runout is 2μ, sealed high-speed grease lubrication, low temperature rise, easy maintenance, and can be used for a long time. The spindle motor adopts a V3-level low-vibration motor. Good concentricity and low vibration. ◆Front and rear screw mechanism The front and rear screws use precision ball screws from Taiwan, China, and telescopic sheet metal shields are used at the front and rear to effectively prevent dust and debris from entering the screws, ensuring long-lasting precision. ◆Imported hydraulic system The hydraulic system is imported from Taiwan, China, and is equipped with a cooling device. Low noise and low temperature rise. The machine can maintain stable precision during long-term operation.

Main Features: ◆High rigidity structure The machine tool body is an integrated structural design. The main castings such as the base, saddle, worktable, frame, spindle head, etc. are all made of high-grade cast iron (FC30) and annealed to eliminate internal stress and ensure the stability of the machine. It also gives full play to the ability of high-precision heavy chip cutting, shortens the grinding time, and improves the working efficiency. ◆High precision The high-precision machine track adopts a double V-shaped track design to ensure the stability of the machine tool worktable. The track is precisely scraped manually to ensure long-lasting accuracy. The feed is smooth and not easy to wear. In addition, the worktable track lubrication is independent lubrication to avoid inaccurate accuracy caused by the heating of the track oil. ◆Precise and strong spindle The spindle adopts imported P4-level precision bearings, with low noise and good precision. The spindle runout is 2μ, sealed high-speed grease lubrication, low temperature rise, easy maintenance, and can be used for a long time. The spindle motor adopts a V3-level low-vibration motor. Good concentricity and low vibration. ◆Front and rear screw mechanism The front and rear screws use precision ball screws from Taiwan, China, and telescopic sheet metal shields are used at the front and rear to effectively prevent dust and debris from entering the screws, ensuring long-lasting precision. ◆Imported hydraulic system The hydraulic system is imported from Taiwan, China, and is equipped with a cooling device. Low noise and low temperature rise. The machine can maintain stable precision during long-term operation. -

Main Features: ◆High rigidity structure The machine tool body is an integrated structural design. The main castings such as the base, saddle, worktable, frame, spindle head, etc. are all made of high-grade cast iron (FC30) and annealed to eliminate internal stress and ensure the stability of the machine. It also gives full play to the ability of high-precision heavy chip cutting, shortens the grinding time, and improves the working efficiency. ◆High precision The high-precision machine track adopts a double V-shaped track design to ensure the stability of the machine tool worktable. The track is precisely scraped manually to ensure long-lasting accuracy. The feed is smooth and not easy to wear. In addition, the worktable track lubrication is independent lubrication to avoid inaccurate accuracy caused by the heating of the track oil. ◆Precise and strong spindle The spindle adopts imported P4-level precision bearings, with low noise and good precision. The spindle runout is 2μ, sealed high-speed grease lubrication, low temperature rise, easy maintenance, and can be used for a long time. The spindle motor adopts a V3-level low-vibration motor. Good concentricity and low vibration. ◆Front and rear screw mechanism The front and rear screws use precision ball screws from Taiwan, China, and telescopic sheet metal shields are used at the front and rear to effectively prevent dust and debris from entering the screws, ensuring long-lasting precision. ◆Imported hydraulic system The hydraulic system is imported from Taiwan, China, and is equipped with a cooling device. Low noise and low temperature rise. The machine can maintain stable precision during long-term operation.

Main Features: ◆High rigidity structure The machine tool body is an integrated structural design. The main castings such as the base, saddle, worktable, frame, spindle head, etc. are all made of high-grade cast iron (FC30) and annealed to eliminate internal stress and ensure the stability of the machine. It also gives full play to the ability of high-precision heavy chip cutting, shortens the grinding time, and improves the working efficiency. ◆High precision The high-precision machine track adopts a double V-shaped track design to ensure the stability of the machine tool worktable. The track is precisely scraped manually to ensure long-lasting accuracy. The feed is smooth and not easy to wear. In addition, the worktable track lubrication is independent lubrication to avoid inaccurate accuracy caused by the heating of the track oil. ◆Precise and strong spindle The spindle adopts imported P4-level precision bearings, with low noise and good precision. The spindle runout is 2μ, sealed high-speed grease lubrication, low temperature rise, easy maintenance, and can be used for a long time. The spindle motor adopts a V3-level low-vibration motor. Good concentricity and low vibration. ◆Front and rear screw mechanism The front and rear screws use precision ball screws from Taiwan, China, and telescopic sheet metal shields are used at the front and rear to effectively prevent dust and debris from entering the screws, ensuring long-lasting precision. ◆Imported hydraulic system The hydraulic system is imported from Taiwan, China, and is equipped with a cooling device. Low noise and low temperature rise. The machine can maintain stable precision during long-term operation. -

Main Features: ◆High rigidity structure The machine tool body is an integrated structural design. The main castings such as the base, saddle, worktable, frame, spindle head, etc. are all made of high-grade cast iron (FC30) and annealed to eliminate internal stress and ensure the stability of the machine. It also gives full play to the ability of high-precision heavy chip cutting, shortens the grinding time, and improves the working efficiency. ◆High precision The high-precision machine track adopts a double V-shaped track design to ensure the stability of the machine tool worktable. The track is precisely scraped manually to ensure long-lasting accuracy. The feed is smooth and not easy to wear. In addition, the worktable track lubrication is independent lubrication to avoid inaccurate accuracy caused by the heating of the track oil. ◆Precise and strong spindle The spindle adopts imported P4-level precision bearings, with low noise and good precision. The spindle runout is 2μ, sealed high-speed grease lubrication, low temperature rise, easy maintenance, and can be used for a long time. The spindle motor adopts a V3-level low-vibration motor. Good concentricity and low vibration. ◆Front and rear screw mechanism The front and rear screws use precision ball screws from Taiwan, China, and telescopic sheet metal shields are used at the front and rear to effectively prevent dust and debris from entering the screws, ensuring long-lasting precision. ◆Imported hydraulic system The hydraulic system is imported from Taiwan, China, and is equipped with a cooling device. Low noise and low temperature rise. The machine can maintain stable precision during long-term operation.

Main Features: ◆High rigidity structure The machine tool body is an integrated structural design. The main castings such as the base, saddle, worktable, frame, spindle head, etc. are all made of high-grade cast iron (FC30) and annealed to eliminate internal stress and ensure the stability of the machine. It also gives full play to the ability of high-precision heavy chip cutting, shortens the grinding time, and improves the working efficiency. ◆High precision The high-precision machine track adopts a double V-shaped track design to ensure the stability of the machine tool worktable. The track is precisely scraped manually to ensure long-lasting accuracy. The feed is smooth and not easy to wear. In addition, the worktable track lubrication is independent lubrication to avoid inaccurate accuracy caused by the heating of the track oil. ◆Precise and strong spindle The spindle adopts imported P4-level precision bearings, with low noise and good precision. The spindle runout is 2μ, sealed high-speed grease lubrication, low temperature rise, easy maintenance, and can be used for a long time. The spindle motor adopts a V3-level low-vibration motor. Good concentricity and low vibration. ◆Front and rear screw mechanism The front and rear screws use precision ball screws from Taiwan, China, and telescopic sheet metal shields are used at the front and rear to effectively prevent dust and debris from entering the screws, ensuring long-lasting precision. ◆Imported hydraulic system The hydraulic system is imported from Taiwan, China, and is equipped with a cooling device. Low noise and low temperature rise. The machine can maintain stable precision during long-term operation. -

Main Features: ◆High rigidity structure The machine tool body is an integrated structural design. The main castings such as the base, saddle, worktable, frame, spindle head, etc. are all made of high-grade cast iron (FC30) and annealed to eliminate internal stress and ensure the stability of the machine. It also gives full play to the ability of high-precision heavy chip cutting, shortens the grinding time, and improves the working efficiency. ◆High precision The high-precision machine track adopts a double V-shaped track design to ensure the stability of the machine tool worktable. The track is precisely scraped manually to ensure long-lasting accuracy. The feed is smooth and not easy to wear. In addition, the worktable track lubrication is independent lubrication to avoid inaccurate accuracy caused by the heating of the track oil. ◆Precise and strong spindle The spindle adopts imported P4-level precision bearings, with low noise and good precision. The spindle runout is 2μ, sealed high-speed grease lubrication, low temperature rise, easy maintenance, and can be used for a long time. The spindle motor adopts a V3-level low-vibration motor. Good concentricity and low vibration. ◆Front and rear screw mechanism The front and rear screws use precision ball screws from Taiwan, China, and telescopic sheet metal shields are used at the front and rear to effectively prevent dust and debris from entering the screws, ensuring long-lasting precision. ◆Imported hydraulic system The hydraulic system is imported from Taiwan, China, and is equipped with a cooling device. Low noise and low temperature rise. The machine can maintain stable precision during long-term operation.

Main Features: ◆High rigidity structure The machine tool body is an integrated structural design. The main castings such as the base, saddle, worktable, frame, spindle head, etc. are all made of high-grade cast iron (FC30) and annealed to eliminate internal stress and ensure the stability of the machine. It also gives full play to the ability of high-precision heavy chip cutting, shortens the grinding time, and improves the working efficiency. ◆High precision The high-precision machine track adopts a double V-shaped track design to ensure the stability of the machine tool worktable. The track is precisely scraped manually to ensure long-lasting accuracy. The feed is smooth and not easy to wear. In addition, the worktable track lubrication is independent lubrication to avoid inaccurate accuracy caused by the heating of the track oil. ◆Precise and strong spindle The spindle adopts imported P4-level precision bearings, with low noise and good precision. The spindle runout is 2μ, sealed high-speed grease lubrication, low temperature rise, easy maintenance, and can be used for a long time. The spindle motor adopts a V3-level low-vibration motor. Good concentricity and low vibration. ◆Front and rear screw mechanism The front and rear screws use precision ball screws from Taiwan, China, and telescopic sheet metal shields are used at the front and rear to effectively prevent dust and debris from entering the screws, ensuring long-lasting precision. ◆Imported hydraulic system The hydraulic system is imported from Taiwan, China, and is equipped with a cooling device. Low noise and low temperature rise. The machine can maintain stable precision during long-term operation. -

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration at high speed, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China*, with low noise and low temperature rise.

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration at high speed, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China*, with low noise and low temperature rise. -

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration at high speed, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China*, with low noise and low temperature rise.

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration at high speed, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China*, with low noise and low temperature rise. -

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration at high speed, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China*, with low noise and low temperature rise.

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration at high speed, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China*, with low noise and low temperature rise. -

◆Guide rails The upper and lower guide rails are made of 40Cr material and are strictly processed through multiple processing procedures. They are matched with SKF-60 wear-resistant materials imported from Germany to ensure long-term and stable upper and lower precision. ◆Lubrication system When the machine is in operation, the automatic circulation lubrication system supplies oil to the guide rails and lead screws to ensure that all key parts can be properly lubricated at any time. ◆Electronic control system The electrical components and functional modules are neatly and orderly installed in the electrical box, making maintenance simple and convenient. ◆High-precision spindle All spindles are installed by experienced technicians of "Dekefuss" in a constant temperature and dust-free workshop, equipped with P4-level ultra-precision angular contact ball bearings and pre-loaded. The bearings are specially selected and combined with the dynamically balanced shaft core to ensure that the spindle runout is within 0.002mm, with low temperature rise, low noise, low vibration, and high-precision grinding. ◆Upper and lower transmission mechanism The upper and lower transmissions are matched with the high-precision turbine worm rods of Japan's Kohara KHK, making the upper and lower transmissions more accurate and smooth. ◆High rigidity machine structure The machine base is made of solid cast iron (FC-30) as a whole. After high-temperature casting, it is subjected to a complete annealing process and aging treatment for more than 6 months to ensure that the machine will not deform after long-term use.

◆Guide rails The upper and lower guide rails are made of 40Cr material and are strictly processed through multiple processing procedures. They are matched with SKF-60 wear-resistant materials imported from Germany to ensure long-term and stable upper and lower precision. ◆Lubrication system When the machine is in operation, the automatic circulation lubrication system supplies oil to the guide rails and lead screws to ensure that all key parts can be properly lubricated at any time. ◆Electronic control system The electrical components and functional modules are neatly and orderly installed in the electrical box, making maintenance simple and convenient. ◆High-precision spindle All spindles are installed by experienced technicians of "Dekefuss" in a constant temperature and dust-free workshop, equipped with P4-level ultra-precision angular contact ball bearings and pre-loaded. The bearings are specially selected and combined with the dynamically balanced shaft core to ensure that the spindle runout is within 0.002mm, with low temperature rise, low noise, low vibration, and high-precision grinding. ◆Upper and lower transmission mechanism The upper and lower transmissions are matched with the high-precision turbine worm rods of Japan's Kohara KHK, making the upper and lower transmissions more accurate and smooth. ◆High rigidity machine structure The machine base is made of solid cast iron (FC-30) as a whole. After high-temperature casting, it is subjected to a complete annealing process and aging treatment for more than 6 months to ensure that the machine will not deform after long-term use.