-

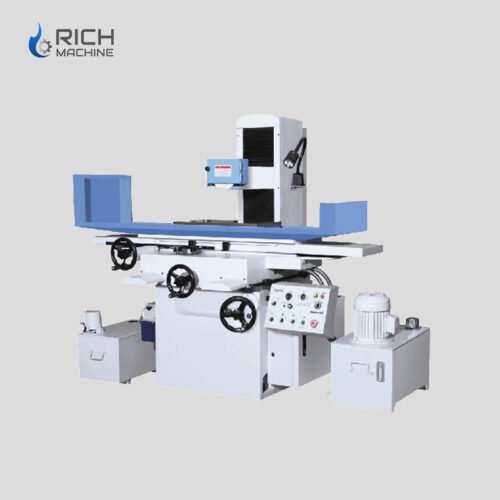

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration under high-speed rotation, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China, with low noise and low temperature rise.

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration under high-speed rotation, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China, with low noise and low temperature rise. -

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration under high-speed rotation, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China, with low noise and low temperature rise.

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration under high-speed rotation, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China, with low noise and low temperature rise. -

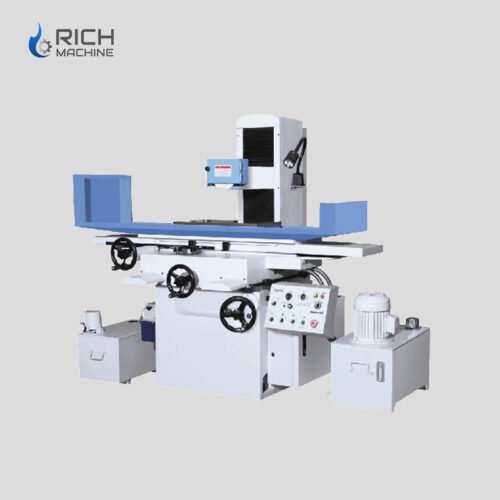

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration at high speed, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China*, with low noise and low temperature rise.

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration at high speed, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China*, with low noise and low temperature rise. -

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration at high speed, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China*, with low noise and low temperature rise.

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration at high speed, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China*, with low noise and low temperature rise. -

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration at high speed, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China*, with low noise and low temperature rise.

Main Features: ◆Angled ball bearings The integral precision spindle used in this machine adopts original P4-grade high-precision bearings, and the spindle motor adopts direct V3-grade low-vibration motor, which has low noise and vibration at high speed, high precision and strong rigidity. ◆High-rigidity structure double V track The double V-shaped track is adopted, and after manual precision scraping, it can ensure long-lasting precision, smooth feeding and low wear; ◆Hydraulic system The hydraulic system is imported from Taiwan, China*, with low noise and low temperature rise. -

◆The integral precision spindle used in this machine adopts original P4-level high-precision bearings, and the spindle motor adopts direct V3-level low-vibration motor, which has low noise and vibration under high-speed rotation, high precision and strong rigidity. ◆The column adopts H-shaped rigid structure and high-rigidity wide-span slide rail design. After precision rail grinding, it has strong rigidity and good precision stability. The column will not deform elastically during forming grinding and grinding, ensuring the processing accuracy and surface finish of the workpiece.

◆The integral precision spindle used in this machine adopts original P4-level high-precision bearings, and the spindle motor adopts direct V3-level low-vibration motor, which has low noise and vibration under high-speed rotation, high precision and strong rigidity. ◆The column adopts H-shaped rigid structure and high-rigidity wide-span slide rail design. After precision rail grinding, it has strong rigidity and good precision stability. The column will not deform elastically during forming grinding and grinding, ensuring the processing accuracy and surface finish of the workpiece. -

◆The integral precision spindle used in this machine adopts original P4-level high-precision bearings, and the spindle motor adopts direct V3-level low-vibration motor, which has low noise and vibration under high-speed rotation, high precision and strong rigidity. ◆The column adopts H-shaped rigid structure and high-rigidity wide-span slide rail design. After precision rail grinding, it has strong rigidity and good precision stability. The column will not deform elastically during forming grinding and grinding, ensuring the processing accuracy and surface finish of the workpiece.

◆The integral precision spindle used in this machine adopts original P4-level high-precision bearings, and the spindle motor adopts direct V3-level low-vibration motor, which has low noise and vibration under high-speed rotation, high precision and strong rigidity. ◆The column adopts H-shaped rigid structure and high-rigidity wide-span slide rail design. After precision rail grinding, it has strong rigidity and good precision stability. The column will not deform elastically during forming grinding and grinding, ensuring the processing accuracy and surface finish of the workpiece.